We discuss the following topics in this blog:

- Short circuits as cause of fires.

- How Fires Cause Massive Loss of Life and Property?

- Can Safe Cabling Prevent Propagation of Fire?

- Low Smoke Zero Halogen (LSZH) Coating

In addition to these topics, we shall also be answering the following FAQs:

- What is WiFi?

- What is an Optical Fibre Cable?

Contents

Overview

In light of the recent unfortunate and ghastly fire accident in Surat, Gujarat, we would like to put some light upon some of the causes and preventive measures that can be taken with focus on cabling.

India saw the deaths of 17,700 people countrywide in fires in both public and residential buildings during 2015 (according to National Crime Records Bureau.) Behind 7% of those, short circuits were the cause of the fires, that’s nearly 1250 lives lost due to faulty wiring.

How Fires Cause Massive Loss of Life and Property?

A major reason why fire is able to cause so much damage to life and property, especially closed buildings, is its ability to propagate throughout the building. It engulfs all the flammable material that comes in its way. It uses them as a medium to propagate and spread from a single location to all over the place causing maximum damage. Along with the sheer heat, fire lowers the oxygen level and also releases smoke with high particulate matter and poisonous fumes. This causes more deaths than the fire itself.

Can Safe Cabling Prevent Propagation of Fire?

Cabling has a huge role to play in this propagation of fire, because of obvious reasons, wires can be found close to the location of where the short circuit initiates. Given the fact that the overall volume of cable is continuously going up in high rise buildings, it becomes very critical to select the right discipline of LAN cabling meeting higher standards of fire compliance. The proper selections of LAN Connectivity enables business efficiency and resiliency through an optimized and well managed cabling infrastructure.

From an interconnected infrastructure perspective, it’s in alignment with the converged cabling connectivity infrastructure approach that we are seeing out in the environment today. It’s really a convergence of the traditional IT systems being video, voice, and data, along with the building systems being WLAN, access and monitoring, lighting, HVAC systems, and so on. Good cabling discipline and well designed networking infrastructure can significantly improve the network performance and improve availability. Selecting proper fire and electrical performance cabling infrastructure up front provides assurance on the correct life-cycle, safety, scalability and flexibility.

PVC as a solution does try to stop the propagation of fire because of its fire resistant nature, but it isn’t fully successful, and has major drawbacks. On coming in contact with water, it releases Hydrochloric Acid, a strong acid that causes damage to other wires & electrical equipment which might lead to short circuits (yes, the medicine can become poison). It also releases dense dark smoke & deadly poisonous fumes of hydrogen cyanide on burning. Its effects vary from irritation in the eyes, nose and respiratory tract, fainting, chronic problems or even death on excess exposure. Thus, it doesn’t solve the problem and needs better performing alternative. CMR or CMP grade PVC which is highly effective against fire turns out to be a little expensive.

Low Smoke Zero Halogen (LSZH) Coating

The need of the hour is Low Smoke Zero Halogen (LSZH) coating. LSZH, limits the smoke by roughly 60% and reduces the amount of poisonous fumes released on its burning by 45% when compared to PVC. It is a much safer alternative to PVC as fire resistant coating for cables. In addition a good LSZH coating is self extinguishing to a certain extent, and will also stop the fire from spreading.

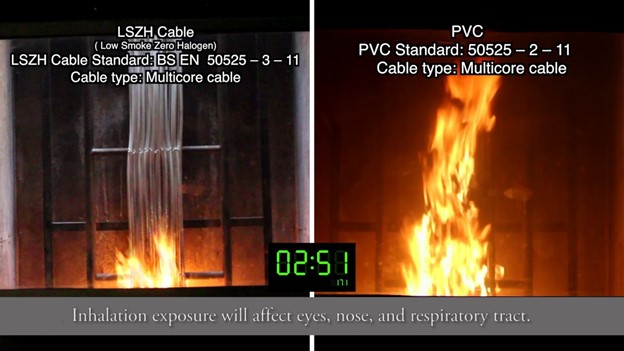

The question arises, where to install the LSZH coated cables. Our research shows a stark difference in PVC cables and LSZH cables when vertically oriented (see image). The fact is that the flames of a fire are able to rise up extremely rapidly due to the inherent nature. Due to this, LSZH is a must when it comes to vertical runs between the floors of a building.

STL includes international third party UL and CPR certified cable designs catering to various needs making our building infrastructures more secure and reliable.

FAQs

What is WiFi?

Put simply, WiFi is a technology that uses radio waves to create a wireless network through which devices like mobile phones, computers, printers, etc., connect to the internet. A wireless router is needed to establish a WiFi hotspot that people in its vicinity may use to access internet services. You’re sure to have encountered such a WiFi hotspot in houses, offices, restaurants, etc.

To get a little more technical, WiFi works by enabling a Wireless Local Area Network or WLAN that allows devices connected to it to exchange signals with the internet via a router. The frequencies of these signals are either 2.4 GHz or 5 GHz bandwidths. These frequencies are much higher than those transmitted to or by radios, mobile phones, and televisions since WiFi signals need to carry significantly higher amounts of data. The networking standards are variants of 802.11, of which there are several (802.11a, 802.11b, 801.11g, etc.).

What is an Optical Fibre Cable?

An optical fibre cable is a cable type that has a few to hundreds of optical fibres bundled together within a protective plastic coating. They help carry digital data in the form of light pulses across large distances at faster speeds. For this, they need to be installed or deployed either underground or aerially. Standalone fibres cannot be buried or hanged so fibres are bunched together as cables for the transmission of data.

This is done to protect the fibre from stress, moisture, temperature changes and other externalities. There are three main components of a optical fibre cable, core (It carries the light and is made of pure silicon dioxide (SiO2) with dopants such as germania, phosphorous pentoxide, or alumina to raise the refractive index; Typical glass cores range from as small as 3.7um up to 200um), Cladding (Cladding surrounds the core and has a lower refractive index than the core, it is also made from the same material as the core; 1% refractive index difference is maintained between the core and cladding; Two commonly used diameters are 125µm and 140µm) and Coating (Protective layer that absorbs shocks, physical damage and moisture; The outside diameter of the coating is typically either 250µm or 500µm; Commonly used material for coatings are acrylate,Silicone, carbon, and polyimide).

An optical fibre cable is made up of the following components: Optical fibres – ranging from one to many. Buffer tubes (with different settings), for protection and cushioning of the fibre. Water protection in the tubes – wet or dry. A central strength member (CSM) is the backbone of all cables. Armoured tapes for stranding to bunch the buffer tubes and strength members together. Sheathing or final covering to provide further protection.

The five main reasons that make this technology innovation disruptive are fast communication speed, infinite bandwidth & capacity, low interference, high tensile strength and secure communication. The major usescases of optical fibre cables include intenet connectivity, computer networking, surgery & dentistry, automotive industry, telephony, lighting & decorations, mechanical inspections, cable television, military applications and space.