The FTTH (Fiber-to-the-Home) industry has experienced significant growth in recent years. To improve deployment efficiency, several changes have been made to the networks, including the introduction of new patching methods for optical fiber cables.

In the past, patching methods were limited and expensive, which hindered the expansion of optical fiber technology. However, the introduction of splicing methods for fiber optic cables has allowed for permanent connections between different cables, overcoming the disadvantages of using optical fiber connectors. Splices are permanent joints, while connectors allow the two fibers to be connected and disconnected at the joint as needed.

Splice connectors are superior to standard fiber connectors because splicing ensures better return loss and insertion loss performance. As a result, industry leaders have standardized the use of splicing, and this article aims to inform readers about the various techniques used for achieving a seamless connection.

Contents

What is optical fibre cable splicing?

Optical fibre splicing is one of the popular techniques for joining two fibre cables to establish prominent connections. Splices allow the connections to offer low optical loss at the joining area with high reliability, which is an advantage for enabling long-distance connections.

Such a technique is also called connecterization or termination and is preferred mostly when two types of cables are joined together. For instance, this method is used for joining a 48-fiber and 12-fiber cable. Upon splicing, the connection will be set for a long run through a unified optical fiber cable.

Splicing will help establish fibre optic communication networks for long-distance signal or data transmission.

Read More: What is Optical Fibre Splice Loss?

How is optical fibre cable splicing better than connectors?

Splicing and connectors both have their advantages and disadvantages, but splicing is generally preferred for long-range transmission networks due to its lower back reflection and ability to fit more splices in a smaller space compared to connectors. Additionally, splicing can be more cost-effective when a large number of joints are required for establishing long-distance optical fibre networks.

The connectors allow the flexibility of changing the various network connections or accessing the temporarily connected cable joins for network testing. But splices are meant for establishing long-range transmission networks, which is the prime USP of optical fibre technology.

So, even though connectors have their efficiencies, how is splicing still better than them?

The first point to prove it is in terms of their size! When you implement a patch panel for the optical fibre connectors, it will take up a lot of space. It will be troublesome mostly when you need a bit of extra space to allow the human hand to enter the patch panel to hold the connector, connecting or disconnecting it.

There’s a type of connector that goes by the name “small-form factor.” Even with the name and size being smaller than usual connectors, it still occupies ample panel space.

The same or more optical fibre cable splices will fit within a thin and small splice tray. Moreover, the splice tray takes up just a fraction of the space that the same number of connectors do.

The splices also have lower back reflection, which is crucial for single-mode fibre optic cable networks. Such a setup works perfectly well when high-speed networks are used for building the backbones or short campuses.

Some of the splices can be quite inexpensive when an industry player seeks a lot of joints for establishing long-distance optical fibre networks. The methods are quite efficient in ensuring the joint loss probability remains low. Hence, splicing is indeed a better alternative than connectors.

Different splicing methods for implementing optical fibre technology

After understanding the advantages of optical fibre cable splicing, it’s important to learn about the two techniques used for creating the splicing connection: mechanical and fusion splicing. The choice of splicing method depends on the specific objectives of the fibre optic connection.

Here is a brief understanding of the two different types of splicing methods for establishing a seamless optical fibre connection:

1. Fusion Splicing

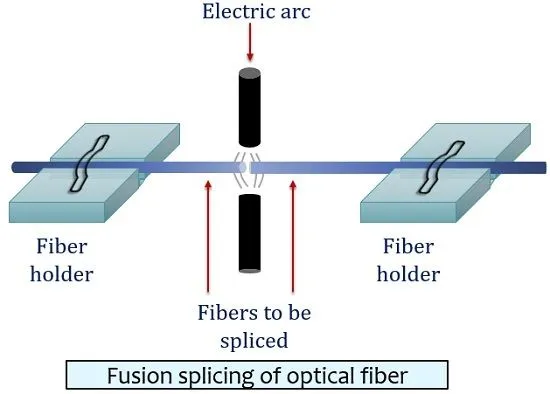

Figure 1: Fusion Optical Fibre Cable Splicing

Image Source: circutglobe.com

It should be noted that while fusion splicing is a commonly used technique for joining optical fiber cables, it may not always be the most widely implemented technique, depending on the specific application or industry. Additionally, while fusion splicing can achieve low attenuation and insertion losses, the exact values may vary depending on the specific fibers and splicing conditions used.

Fusion splicing uses the process of efficient welding to bring the two fibre cables together. An electric arc is used for the process, which ensures the least reflection and the lowest possible loss.

Apart from that, fusion splicing of the optical fibre cables ensures that the joint is extremely strong and highly reliable between the two fibres. Fusion splicing can be achieved through a fusion splicer, a special piece of equipment used for the purpose. The fusion splicer is responsible for aligning the joints of two fibre cables and then melting them together to establish the connection.

The connection has a long life with a low attenuation of around 0.1 dB. Moreover, the insertion losses are less than 0.1 dB in both multimode and single-mode fibre optic cable splicing. However, it is also more expensive than mechanical splicing.

The applicator must ensure that the heat generated for melting the fibre cable joints is at an optimal temperature. If there’s any kind of excessive heat, then the fibre cable joint will become delicate. Thus, it won’t run proficiently for a long time. Once the connection is established, the joining junction will be covered with a plastic coating or polyethylene jacket for protection.

Pros:

- Offers low variable cost for every fusion splice attained.

- Offers low insertion loss with better performance.

- The environment is more secure, with fewer cable failures.

- Supports lowest back reflection

- Highest mechanical strength

- Quick & worry-free process

- An ideal choice for single-mode fibre optic cable connections

Cons:

- The upfront cost of fusion splicing is pretty high.

- It demands a consistent supply of power and some special tools.

- Needs regular and timely cleaning.

2. Mechanical Splicing

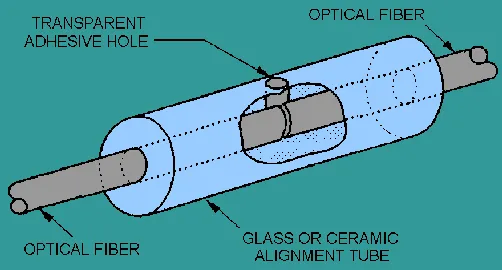

Figure 2: Mechanical Splicing Diagram

Image Source: tpub.com

Mechanical splicing is a simpler form of splicing for the optical fibre cable, which undergoes simple alignment and design for holding two cables together with the help of a self-contained assembly. In the case of mechanical splicing, the two cables do not undergo permanent joining but are held together in such a way that light can pass from one fibre cable to the other.

This approach is popular for splicing multimode fibres on-premise. Moreover, it also supports the temporary and fast restoration of the network or connection. Some organisations also prefer using mechanical slices temporarily for testing all of the bare fibres with OLTs (optical line terminals) or OTDRs (optical time-domain reflectometers).

In comparison to fusion splicing, mechanical splices result in higher loss and reflection. But one way mechanical splices lead the way is that they don’t need an additional machine to conduct the splicing process. The person handling the splicing technique will need standard cable preparation tools and a cleaver for executing the process.

Mechanical splicing is again divided into V-grooved and elastic-tube splicing. For the V-grooved splicing, a V-shaped substrate is taken across two fibre ends and placed within the groove. Once both fiber ends are placed within the groove, ensuring proper alignment, you will be bonded through the index gel or adhesive. Thus, there will be optimal grip within the connection.

On the other hand, elastic-tube splicing is executed using a tube, which is preferable for multimode optical fibre splicing connections. The fibre loss observed with this mechanical splicing technique is nearly the same as that of the fusion splicing technique.

An elastic tube with a hole smaller than the optical fibre cable is obtained. When the fibre cable is inserted within the tube, there will be a symmetrical force that will trigger expansion. Proper alignment is then achieved within the two fibres.

Pros:

- Mechanical splices do not require any external power source, but they do require some tools such as a cleaver and strippers for preparing the fibers.

- While mechanical splicing is generally less expensive than fusion splicing, it may still require some specialized equipment depending on the specific splice design.

- Mechanical splicing may be a viable alternative when fusion splicing is not possible or practical, but it may not always be the best choice depending on the specific application.

Cons:

- Insertion loss can vary depending on the specific splice design and fiber type, but it is generally higher than for fusion splicing.

- Mechanical splicing can be used for both multimode and single-mode fibers, but the specific splice design may depend on the type of fiber being spliced.

- The durability of mechanical splices may depend on the specific splice design and installation conditions.

So, it is quite evident that both mechanical and fusion splicing have their benefits and drawbacks for the industry. But whether one should go with fusion or mechanical depends on various elements, including signal loss, reflection needs, and transmission distance.

If you intend to learn more about optical fibre cable splicing, then check out our solutions at STL Tech.

Frequently Asked Questions

The potential difference between a connector and a splice is that the connector joins two ends of the fibre cable temporarily, which is used for modifying or repairing the network in the long run. As a result, the optical fibre technology couldn’t see transmission over long distances. Therefore, splices were used for this purpose! Splices make a permanent connection within the two optical fibre cables, supporting transmission over long distances.

While splicing techniques have their advantages over fibre connectors, it may not be entirely accurate to say that they are “better to all extents.” It ultimately depends on the specific application and requirements.

That being said, some potential benefits of using splicing techniques over fibre connectors include:

- Lower signal loss: Splicing can result in lower signal loss than connectors, which can be particularly important for long-distance transmissions.

- Greater reliability: Splicing can provide a more secure and permanent connection, as there are fewer potential points of failure than with connectors.

- Better environmental protection: Splicing can provide better protection against environmental factors such as moisture and temperature fluctuations, which can be particularly important for outdoor installations.

It’s also worth noting that splicing techniques typically require more specialized tools and expertise, and can be more time-consuming and expensive than using connectors.

Fusion splicing has more perks in comparison to the mechanical splicing approach. The splice’s performance as a unified cable, due to the welding of fibre joints, is what leaves mechanical splicing behind in terms of popularity and functionality. Moreover, fusion splicing creates a stronger bond between the two cables, which lasts longer. However, it’s important to note that there are situations where mechanical splicing might be more appropriate or cost-effective, such as in temporary splicing or when working with multimode fibers. Therefore, it’s always important to consider the specific requirements and limitations of a project before deciding on a splicing method.