We discuss the following topics in this blog:

- STL enabled “Massive Intra-Plant Connectivity”.

- Industry 4.0 for manufacturing facilities

- STL Gaurav project.

In addition to these topics, we shall also be answering the following FAQs:

- What is WiFi?

- What is an Optical Fibre Cable?

Contents

How STL is Powering This Mega Industry 4.0 Plant?

Industry 4.0 is the new buzzword for manufacturing facilities and STL is a global technology leader, with its feet firmly grounded in manufacturing excellence and wings widely spread in digital communications landscape.

What can be better than one enabling the other.

The Power of STL in STL!

We have created, not a miniature, but a full blown model of a colossal 4.0 plant, completely running on STL backbone and platforms.

Project Gaurav is one of the world’s largest greenfield glass plants, which will take STL’s optical fibre capacity to a whopping 50 million fkm annually.

Built on the fundamentals of the smart factory model, the plant leverages the power of automation, IoT and robotics to deliver the highest yield throughput capacity.

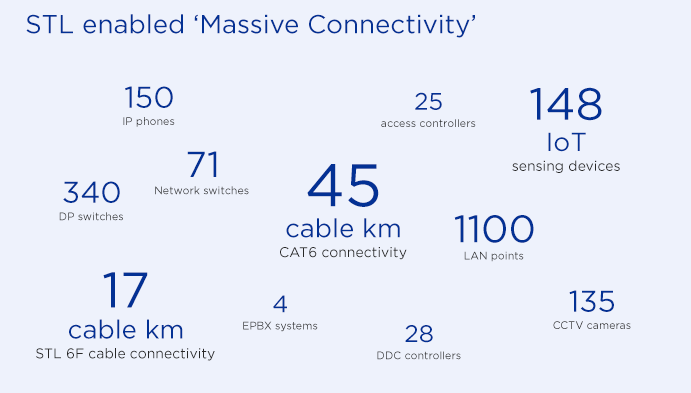

An ecosystem of intelligent machines, cloud & cognitive computing and cyber-physical systems is running on STL enabled “Massive Intra-Plant Connectivity”

How Unique “STL in STL” Combination has Helped us Create a Model Plant?

Here is a list down of all the things “STL” @ Gaurav

- STL optical solutions for network backbone – 100% of Plant Gaurav data travels on our innovative, cutting edge 6F optical fibre cables.

- Highly reliable access & control network – in both glass and draw plants

- CAT6a cables for end user connectivity – Creating an end user ecosystem with thousands of seamlessly connected people and devices

- STL’s IPBX system – Telephone network for the plant runs on Neox, our VOIP IPBX system manages 150 IP phones and connects users across various departments

- Building management system – of huge premises runs on STL connectivity solutions

- CCTV network – across plant premises enabled by STL network

FAQs

What is WiFi?

Put simply, WiFi is a technology that uses radio waves to create a wireless network through which devices like mobile phones, computers, printers, etc., connect to the internet. A wireless router is needed to establish a WiFi hotspot that people in its vicinity may use to access internet services. You’re sure to have encountered such a WiFi hotspot in houses, offices, restaurants, etc.

To get a little more technical, WiFi works by enabling a Wireless Local Area Network or WLAN that allows devices connected to it to exchange signals with the internet via a router. The frequencies of these signals are either 2.4 GHz or 5 GHz bandwidths. These frequencies are much higher than those transmitted to or by radios, mobile phones, and televisions since WiFi signals need to carry significantly higher amounts of data. The networking standards are variants of 802.11, of which there are several (802.11a, 802.11b, 801.11g, etc.).

What is an Optical Fibre Cable?

An optical fibre cable is a cable type that has a few to hundreds of optical fibres bundled together within a protective plastic coating. They help carry digital data in the form of light pulses across large distances at faster speeds. For this, they need to be installed or deployed either underground or aerially. Standalone fibres cannot be buried or hanged so fibres are bunched together as cables for the transmission of data.

This is done to protect the fibre from stress, moisture, temperature changes and other externalities. There are three main components of a optical fibre cable, core (It carries the light and is made of pure silicon dioxide (SiO2) with dopants such as germania, phosphorous pentoxide, or alumina to raise the refractive index; Typical glass cores range from as small as 3.7um up to 200um), Cladding (Cladding surrounds the core and has a lower refractive index than the core, it is also made from the same material as the core; 1% refractive index difference is maintained between the core and cladding; Two commonly used diameters are 125µm and 140µm) and Coating (Protective layer that absorbs shocks, physical damage and moisture; The outside diameter of the coating is typically either 250µm or 500µm; Commonly used material for coatings are acrylate,Silicone, carbon, and polyimide).

An optical fibre cable is made up of the following components: Optical fibres – ranging from one to many. Buffer tubes (with different settings), for protection and cushioning of the fibre. Water protection in the tubes – wet or dry. A central strength member (CSM) is the backbone of all cables. Armoured tapes for stranding to bunch the buffer tubes and strength members together. Sheathing or final covering to provide further protection.

The five main reasons that make this technology innovation disruptive are fast communication speed, infinite bandwidth & capacity, low interference, high tensile strength and secure communication. The major usescases of optical fibre cables include intenet connectivity, computer networking, surgery & dentistry, automotive industry, telephony, lighting & decorations, mechanical inspections, cable television, military applications and space.