Interconnectedness is increasingly becoming the backbone of a modern, progressive world. It is what is driving the escalation of digital transformation of every aspect of our lives, resulting in an ever-increasing demand for faster, low-latency, and higher throughput data.

For decades, interconnects that form the key connecting blocks of our network architecture have handled this demand admirably. In that regard, both optical interconnect and electrical interconnect bring their unique benefits towards supporting high-performance parallel networks. In a nutshell, these interconnects do exactly what they denote through their nomenclature: they connect critical devices, enabling transmission of data and power between them. This is where optical interconnect vs electrical interconnect always makes for an interesting debate.

While the former operates on the basis of increasingly preferred fiber optics technology, the latter represents an evergreen solution that deploys copper cables and more cost-effective components. Both have distinct differences that make them better suited for certain applications.

In this blog, we will attempt to highlight the difference between optical interconnect and electrical interconnect – and aim to answer which of these technologies is best positioned to meet performance requirements in future systems.

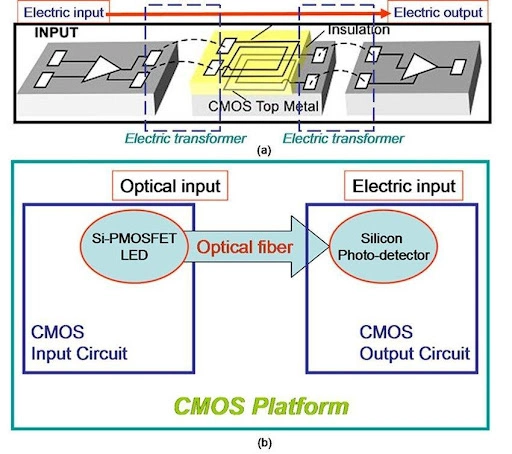

(a) Electrical interconnect vs (b) Optical interconnect

Contents

Optical Interconnect and Electrical Interconnect: An Overview

Optical interconnect and electrical interconnect – both remain key pieces of the communication infrastructure paradigm. In layman’s terms, an interconnect is a cable or connection which can link two or more devices electrically or optically. This allows efficient transmission of data and power between server to server, rack to rack, module to module, backplane to backplane, board to board, and chip to chip configurations found in network architecture, data centers and ICT devices.

Optical interconnects deploy fiber optic cabling to achieve the linkage whereas electrical interconnects use traditional copper wiring. Typically, network providers and manufacturers have opted for electrical interconnects for their low initial costs, simplicity and ease of deployment. They have preferred optical interconnects only in the case of high-performance systems that seek to establish longer-distance network links, thanks to their lower attenuation properties.

However, the rise of next-generation network architectures, data architectures, and deep fiberisation is pivoting manufacturers, operators and providers toward optical interconnect technology. Doing so is necessary to speed up the adoption of FTTH, and 5G and better serve IoT use cases.

Optical interconnect network for high-performance systems

Ultimately, the speed at which data and network technology are changing means operators, device manufacturers and data centers have to opt for the right interconnect technology so as to prevent system performance bottlenecks. They also have to ensure that either of optical interconnect and electrical interconnect used must future-proof the network architecture in terms of its throughput, latency, and density advantages.

In doing so, they must consider myriad factors that separate the two: reliability, speed, latency, throughput, cost, power, density, reach, etc.

Difference Between Optical Interconnect and Electrical Interconnect: 8 Factors

1. Speed

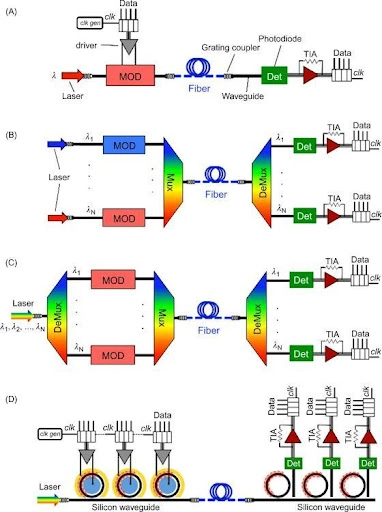

One of the most significant differences between optical interconnects and electrical interconnects is the speed and distance at which they can transmit data. Optical interconnects use light to transfer data, which allows for faster data transmission speeds.

According to a study by Cientifica Research, it is possible to achieve 100 Gbps data transfer with optical interconnects, while electrical interconnects typically have data transfer rates of up to 40 Gbps. However, the speed advantage of optical interconnects decreases as the distance between devices increases.

Thus, optical interconnects generally have higher data transfer rates compared to electrical interconnects, making them suitable for high-bandwidth applications such as high-definition video streaming.

2. Distance

Distance also represents a key difference between optical interconnect and electrical interconnect. Optical interconnects can send data across longer distances than electrical interconnects. The reason? Light can travel through optical fibers without experiencing signal degradation, while electrical signals can degrade over longer distances. This makes optical interconnects an ideal option for long-distance applications such as telecommunications and data centers.

According to a report by the National Renewable Energy Laboratory, optical interconnects have a data transmission range of up to 100 meters, while electrical interconnects typically have a maximum transmission distance of 10 meters.

3. Cost

As optical technology becomes more cost-efficient, we can expect optical interconnects to eventually go shoulder to shoulder with the cost-effectiveness of electrical interconnects. For now, electrical interconnects continue to be generally less expensive. A report by IHS Markit states that the cost of electrical interconnects can be up to 50% less than the cost of optical interconnects.

But there is an important caveat. In the long term, optical interconnects have a more effective cost of operation. Low maintenance, efficient power consumption, and longer shelf life contribute to this cost-effectiveness for optical interconnects. Additionally, optical interconnects can last for decades, which reduces the need for frequent replacements. A fiber optic patch cable for example, is a cost-effective solution for short-distance applications that require high-speed data transmission.

4. Power consumption

Optical interconnects typically require more power compared to electrical interconnects, making them less suitable for use in portable or low-power devices. However, overall operational costs for optical interconnects installed in large-scale network architecture comes out to be much more reasonable.

5. Reliability and durability

Another key difference between optical interconnects and electrical interconnects is their reliability and durability. Optical fibers are immune to electromagnetic interference (EMI) and radio frequency interference (RFI), which means that they are less likely to experience signal degradation or errors. This makes optical interconnects more reliable than electrical interconnects, which can be affected by EMI and RFI.

Additionally, optical fibers are more durable than electrical wires and cables. They are resistant to wear and tear, and are not affected by temperature changes or physical stress. This makes optical interconnects a better option for applications that require long-term stability and reliability.

6. Complexity

Optical interconnects can be more complex to implement compared to electrical interconnects, as they require specialized optical components such as transmitters, receivers, and fiber optic cables. This complexity can lead to longer lead times and higher initial costs, making optical interconnects a less attractive solution for some applications. However,

7. Flexibility

Both optical interconnect and electrical interconnect technologies offer a similar degree of flexibility, depending upon the environment in which they operate. Traditionally, electrical interconnects are considered more flexible than optical interconnects, as they can be easily connected and disconnected and can be used to transmit power as well as data.

However, as we build more and more fiber deep networks and disaggregated data centers, the flexibility and scalability of having optical interconnects cannot be stated enough. They consist of a wide product range of products and devices for compatibility across network bandwidths and categories. These include servers, storage systems, network switches, and more – all available in the form of ‘plug-and-play’ modules for seamless network architecture upgradation.

8. Applications

Optical interconnects are commonly used in high-definition video, data-intensive applications, and telecommunications. They are especially becoming popular in disaggregated data centers. On the other hand, electrical interconnects are still widely used in certain applications. They are commonly used in personal computers, consumer electronics, and other devices that require low-speed, low-bandwidth data transmission over short distances.

Optical Interconnect vs Electrical Interconnect: Making a Case

In conclusion, optical interconnects and electrical interconnects have distinct differences that make them better suited for specific applications. While optical interconnects offer faster data transmission speeds, longer distances, reliability, durability, and cost-effectiveness, electrical interconnects are still widely used in low-speed data transmission applications.

Ultimately, when choosing between the two technologies, it is important to consider the specific requirements of your application and the long-term benefits of each technology. In recent years, there have been many advancements in the field of electrical interconnects, including the development of new interface standards and improved connector designs, which have improved performance and reliability. However, with the right solution, optical interconnects can help your business or industry to stay competitive and ahead of the curve.

Overall, as the demand for faster data transmission speeds and longer distances continue to grow, we can expect to see more and more companies and industries adopting optical interconnect technology.