The demand for high-capacity, low-cost networks has seen massive growth in the last few years. This has compelled mobile network operators to upgrade access technologies from 2G and 3G to 4G and beyond. Similarly, wireline access networks, or WANs, have moved from DSL and coaxial to fiber to the home (FTTH).

Contents

What Is an Aerial Cable in Fiber Optics?

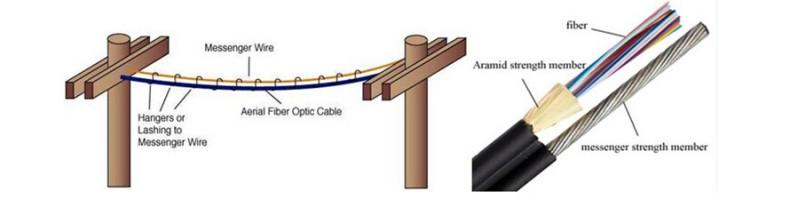

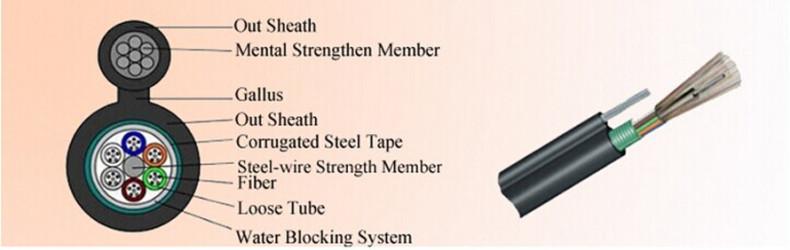

Aerial cable types are typically used for outdoor aerial installation on poles. Its characteristic lies in its design, which is structured according to its installation environment.

Since these cables are installed outside, aerial fiber optic cables are strong enough to withstand natural calamities and man-made damage or theft. Aerial cables are mainly used at the secondary trunk level and below. This type of cable is helpful for flat terrain or low-lying areas prone to fewer fluctuations.

The installation method of aerial cables is simple to implement. They can utilize the existing overhead lines on the poles outside on the roads. This leads to shorter construction periods and a reduction in construction costs.

Types of Aerial Fiber Cable

Aerial fiber optic cables are of two types, according to the installation methods.

- Catenary wire

- Self-supporting

Catenary Wire Aerial Cable

Aerial cables of the catenary wire type are the regular outdoor cables in loose tubes. They can be entwined with another cable or a messenger cable.

The catenary cables use the following components:

- Main messenger wire

- Sub-messenger wire

- Cable

- Cable rings

During the temporary installation of such a cable or when attaching cable rings, the technicians have to work in mid-air. They use a specially designed tool to fix the main messenger wire to the sub-messenger wire. It takes a long time to install an additional cable. Cable replacement takes even more time.

Self-Supporting Aerial Cable

Self Supporting Aerial Cable is also known as All Dielectric Self-Supporting or ADSS cable. These are the commonly used Figure-8 aerial cables. It consists of a cable wrapped in insulated steel or the ADSS messenger cable for support.

ADSS is a non-metallic fiber optic cable that can be installed without the assistance of a metal strand. These cables can be attached directly to the pole or tower with special attachment hardware.

ADSS cables have heavy jackets of stronger metal. People more widely use these aerial fiber optic cables. Figure-8 self-support aerial cables follow a one-step installation, which is easy and economical. They are commonly used in network communication and for long-haul networks.

There are several kinds of Figure-8 self-supporting aerial fiber cables in the market based on the material and structure of the cable. Various Figure-8 cables are available, such as GYTC8S, GYXTC8S, and GYXTC8Y.

Aerial Fiber Cable Installation Methods

Optical fibers are mechanically very different from regular metallic cables. Therefore, the techniques for installing them are also different. In addition, these fibers are extremely brittle, but at the same time, they are also elastic to some extent.

There are multiple aerial fiber cable products available on the market today. There are presently two types of solutions available:

- By installing fiber into an aerial drop tube

- By deploying a self-supporting, standalone cable

Splice Box

For both approaches, a splice box or a fiber enclosure box is used. This splice box is a splice distributor, which is a place where fiber optic cables begin or end. It acts as a junction box to connect various fiber optic cables.

Fiber optic cables come from these splice boxes, which are located at the ends of fiber optic transmission paths. They come in different configurations, such as wall mounts, rack mounts, and indoor or outdoor mounts.

Let us take up the first fiber aerial cable laying method.

Fiber Aerial Cable Laying Method

Aerial installations use both armored and dielectric fiber-optic cables. Dielectric cables protect against lightning strikes and electrical crossovers from power lines as they don’t have metal components.

Before starting the installation, cable technicians need to take care of some installation procedures.

- They need to perform a pre-survey. This field survey involves planning the cable route and finding which aerial cable installation method has to be used. Based on that, the technicians will determine the material and equipment requirements.

- Next, the technicians need to investigate the ground conditions, including clearance problems over driveways, roadways, fields, etc.

- Technicians also need to select splice locations. This is necessary to verify the transmission design and determine the cable order lengths.

The choice of the installation or placement method will be based on the conditions at the construction site and the availability of equipment and manpower there. There are two methods for aerial installation:

- Back-pull or Stationary reel method

- Drive-off or Moving reel method

Back-pull or Stationary Reel Method

This is the most commonly used method of cable placement. The stationary method is used when there are several obstructions in the cable area, such as trees, houses, etc. So, the reel-carrying vehicles are not able to drive through most of the cable routes.

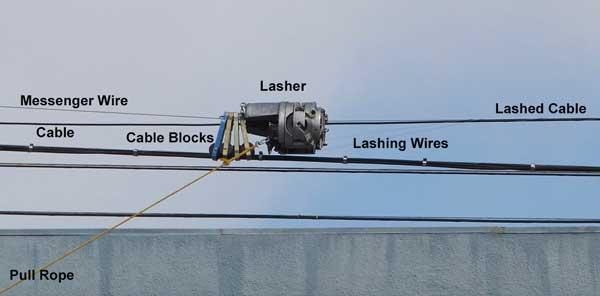

Using this method, technicians use cable blocks to pull the fiber optic cable into place beneath the strand. Here, the cable runs from the reel to the strand. A forward-moving block pulls it, and cable blocks uphold it. Excess slack loops are formed after that.

Once the cable is pulled, cable lashing to the strand begins from the far end of the cable. Here, the stationary reel located at the other end pulls the lasher.

Drive-off or the Moving Reel Method

The drive-off method of cable placement is especially applicable when the pre-survey of the area shows that there are no trees or other hurdles to prevent raising the cable to the suspension strand. There should also be access for vehicle placement on the side of the pole where the laying of the cable is needed.

In the moving reel or drive-off method, the cable is attached to the strand. Cable laying happens as the reel moves away from it. The cable lashing happens as it is being pulled. As the cable is lashed, the excess slack forms loops. The drive-off method saves time in cable placement and lash-up. It also takes less manpower.

Deploying a Self-Supporting or Stand-Alone Cable

Aerial cables can also be mounted on buildings or suspended from poles or towers. Such types of cables are self-supporting cables. They don’t require any separate messenger wire for cable weight support. Drop cables are widely used in FTTH networks.

Standalone or drop cables have an intersecting face, representing the figure of the number 8. Self-supporting drop cable has metal hanging units that provide it with strong tensile strength. The conventional drop cable consists of two parallel reinforced core cables with an optical fiber in between.

The aerial drop cable is designed to run from the distribution point to the subscriber. Their metal units will be clipped before they enter the subscriber box. Aerial drop cables are more expensive than regular drop cables.

Wrapping Up

Installing aerial cables is not a simple task. Aerial cable installations need extra concentration and patience. Proper precautions need to be taken while installing the cables. Typically, the fiber-in-duct approach can be made in two phases of installation. In the second approach, the self-supporting aerial cables can be deployed in one installation phase alone. Thus, the self-supporting cable solution costs less in terms of labor.