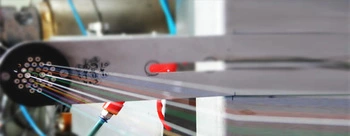

The wet primary coating has been applied on the surface of optical fiber during the draw process to lower the micro-bend induced attenuation.The viscous stress is induced on the surface of fiber during the coating application due to use of high viscous coating material and drawn in high speed. The viscous stress decreases the mechanical strength of the fiber and it has been calculated using Computational Fluid Dynamics (CFD) simulation tool. It is found that the normalized maximum viscous stress decreases from o o 2.45 units to 1.1 units as the coating temperature increases from 40 C to 60 C.

The wet coating system has been applied on the surface of optical fiber during its draw process. The wet primary coating lowers the micro-bend induced attenuation whereas the wet secondary coating provides the mechanical strength to the fiber. There has been market demand to decrease the manufacturing cost of optical fiber and hence, the draw tower are being designed to draw the fiber at high speed at the range of 30-40 m/s. The high draw speed manufacturing process demands the redesigning of coating applicator to control the coating thickness.