Around five decades back, scientists and engineers realised something that gave way to a great technological breakthrough. Traditional copper-based communication systems, with their limitations, could no longer keep pace with the growing demands of a hyper-connected world.

In a world bustling with technological advancements and interconnectedness, a remarkable story unfolds. The story reveals the vital role played by tiny particles of sand in shaping the digital landscape we inhabit today.

Welcome to a tale that unravels the secrets of how the world’s reliance on fibre optics came to be.

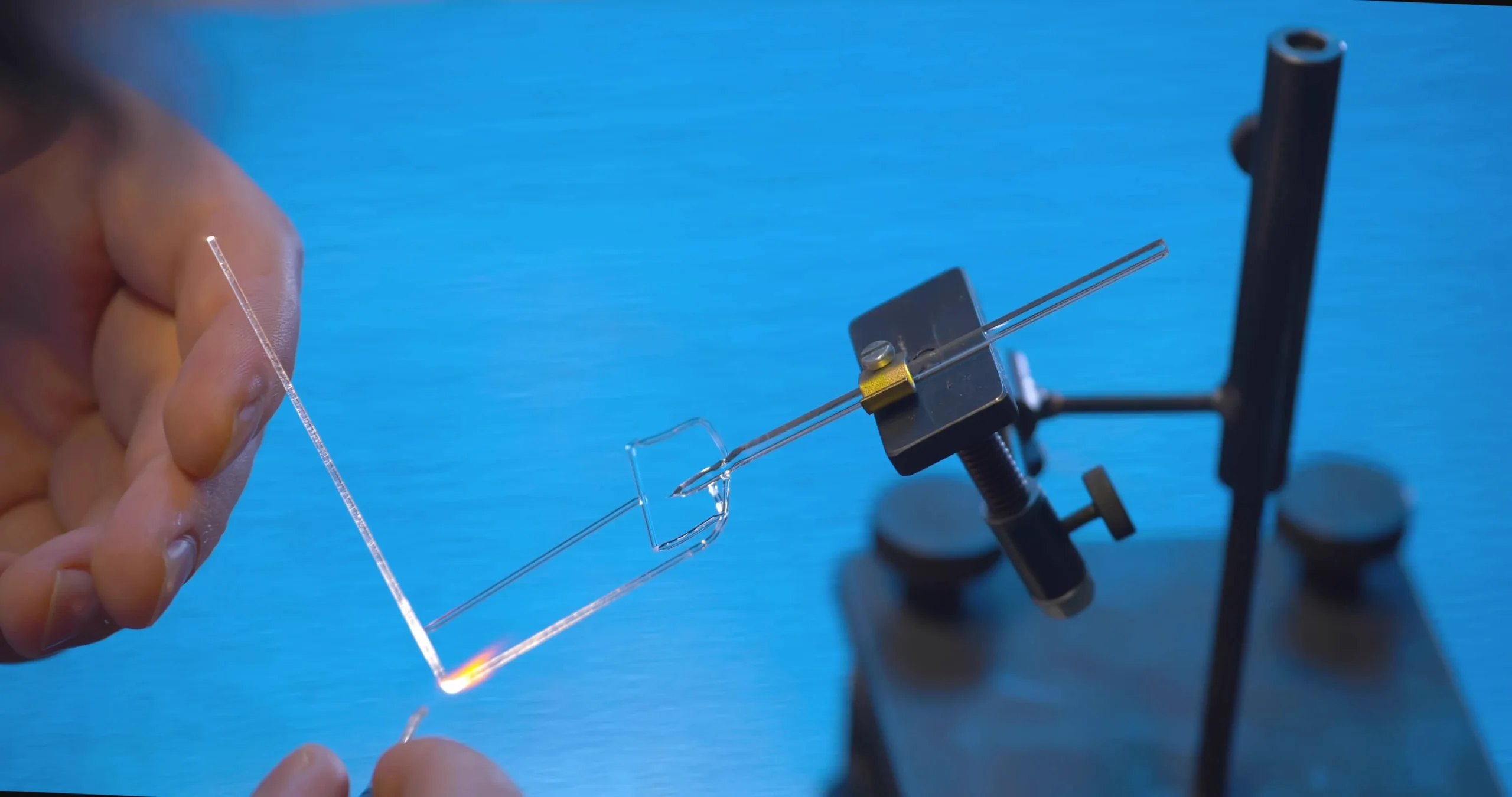

Once upon a time, in an era defined by the boundless possibilities of the internet, humanity craved a medium through which information could travel swiftly and seamlessly across distances. Harnessing their expertise, the scientists meticulously refined silica, transforming it into an ultra-pure form suitable for the demands of optical communication. This refined silica became the foundation of a revolutionary technology – fibre optics.

This year marks the 51st anniversary of the breakthrough that enabled connectivity for billions. In 1970, a team of scientists employed by a glass manufacturing company developed a technique to create high-purity silica glass from sand. This silica glass was converted into preform from which hair-thin strands of optic fibre are derived, which are the backbone of modern network infrastructure.

With fibre optics, the internet could now travel at the speed of light, unencumbered by the limitations of traditional communication mediums. Light, guided by the incredibly transparent fibres made from refined silica, could carry vast amounts of data across continents in mere moments.

The world witnessed a remarkable shift as fibre optics became the backbone of the digital age. It fueled e-commerce and global collaborations and transformed the way industries operated.

The remarkable speed and efficiency of the internet transcended boundaries and connected people from every corner of the globe.

India is one of only six nations globally who have the technology to create the glass preform from sand. Glass preform is the core component of optical fibre on which the global broadband internet runs.

Mastering the art of converting sand to fibre

The world had long been fascinated by the magic of transforming ordinary sand into something extraordinary—glass. For centuries, engineers and scientists had mastered the art of melting sand, which predominantly comprised silica, and witnessed its metamorphosis into shimmering, translucent structures.

However, despite their skill in making glass, they encountered a recurring challenge. While the glass they created possessed its own charm, it lacked the vital quality of optical transparency needed to transmit light over long distances efficiently.

Enter the visionary minds of STL, a pioneering force with three decades of expertise in the realm of materials science and optical fibre technology. Fueled by an insatiable curiosity and a passion for innovation, the scientists of STL embarked on a quest to revolutionise digital connectivity.

Drawing inspiration from the sands, the researchers at STL discovered the inherent magic hidden within the tiny particles of sand—silica. With its unique optical properties, silica held the key to ushering in a new era of lightning-fast information transmission.

To overcome this obstacle and fulfil their dreams of crafting glass preform, STL started producing its own refined silica to ensure the desired level of optical purity essential for effective light transmission. STL was renowned for its innovative advancements in materials science. Deep within the laboratories of STL, scientists worked tirelessly, conducting experiments and searching for ways to enhance the optical purity of silica. They meticulously developed techniques to extract impurities, ensuring that the refined silica possessed the desired level of clarity and transparency. With their expertise and dedication, they were able to eliminate imperfections that hindered light propagation, creating silica of exceptional quality.

STL’s refined silica became the heart and soul of light transmission, the glass preform of optical fibre. STL’s commitment to producing the finest silica from sand persisted, driven by a profound understanding of the impact it could have on the world in the future. With every batch refined to perfection, they pushed the boundaries of what was possible, continually raising the bar for optical purity.

They were able to weave this magic through their world-class glass plant in Aurangabad, Maharashtra

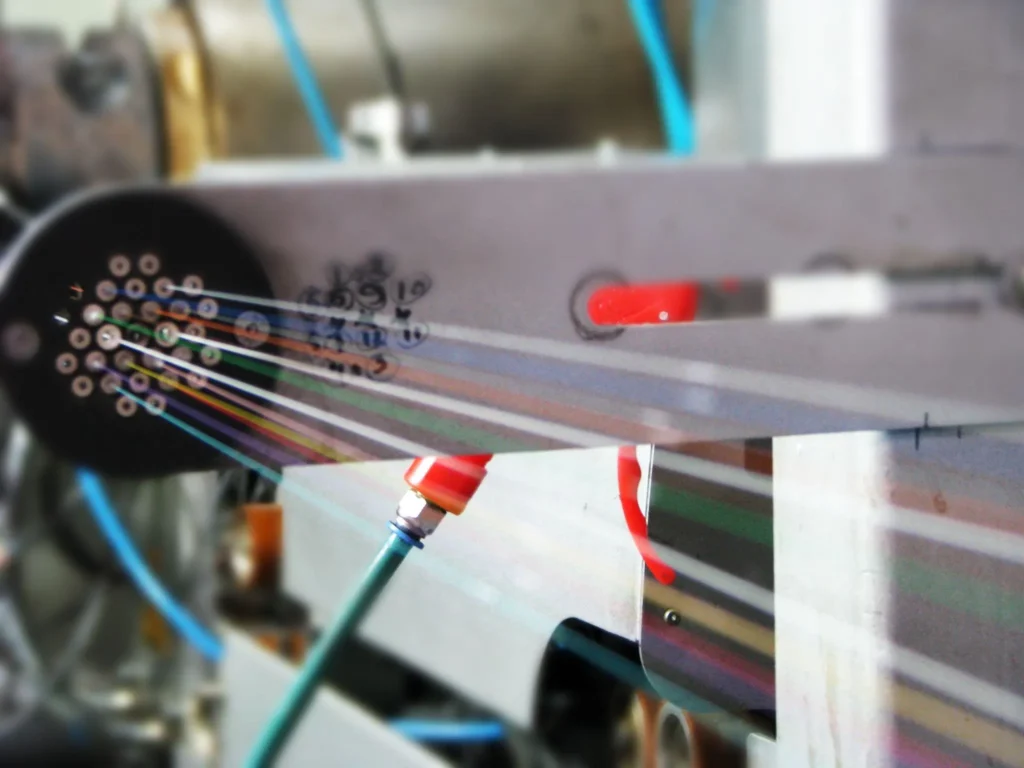

A state-of-the-art glass plant is taking the magic of connectivity to billions

STL’s glass Plant in Aurangabad, Maharashtra, is India’s most advanced Industry 4.0 first-ever glass manufacturing facility. The plant is dedicated to manufacturing Glass Preforms, which are used to draw world-class optical fibre. These semiconductor grade Glass preforms are the biggest driver of the high quality and longevity of fibre networks.

It has IoT-based automation, digital twins for equipment, sensor-based asset monitoring and defect detection through computer vision and machine learning. This cyber-secure technology platform integrates all layers of automation. It enables data-led decision-making to deliver increased Overall Equipment Effectiveness (OEE), optimal asset utilisation, better response times and lower failure rates.

This plant is India’s largest clean room facility, where the key equipment is maintained at the most stringent standards of Class 1000. The factory employs India’s top talent of 300+ researchers and engineers and is a testimony of India’s prowess in intellectual property-led hi-tech manufacturing.

The plant will be a key support for India to achieve 100% self-reliance Atmanirbharta in Optical fibre. It is now running at its full capacity to support the imminent 5G and Bharatnet networks being built now.

The Industry 4.0 plant is bringing together technology innovation that will enable 5G and rural connectivity in India and allow new, faster and highly scalable 5G network build-outs, transforming billions of lives.

In addition to the Glass plant, STL has 5 more facilities for optical fibre, cable and interconnect across Maharashtra.

This is a story of relentless pursuit, unwavering passion, and a commitment to transforming the ordinary into the extraordinary. Through their groundbreaking work, STL has given the world a gift of pure, refined silica, an indispensable ingredient in the alchemy of light transmission.

As you read this story, connected to the global internet, remember the extraordinary journey that started with the humble particles of sand, transformed into refined silica, and how it gave birth to the transformative power of fibre optics. This invisible web now intertwines our lives and shapes our shared future.

Next time whenever you visit a desert and see sand, just think that these sand particles are going to create unmatched connectivity for billions more…