Substituting ribbons for individual fibers within an optical cable allows the fiber to be packed more compactly within the cable whether it is a multi-tube or central tube cable. Ribbon cables are smaller in size and weight and generally easier to handle than comparable individual fiber based cables. The net result is ribbon cables are easier for the installation crew to handle and place.

What is a Ribbon Optical Cable?

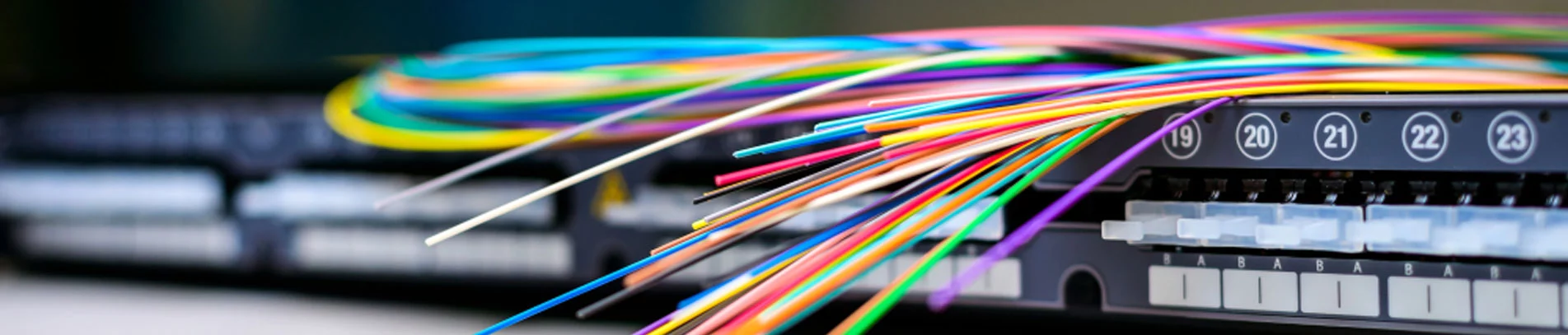

Optical fiber ribbons are made up of individual fibers aligned in a single row then impregnated with an acrylate UV curable resin. Multiple individual optical ribbons can be stacked into a bundle with a matrix structure and stored in a central core-tube or in stranded multi-tubes in the cable core to optimize the fiber packing density within the cable.

Fiber ribbon cables are described by several international standards bodies, including the International Electrochemical Commission (IEC) and the Insulated Cable Engineers Association (ICEA). Optical ribbons are specified as part of the IEC 60794-series of specifications and several of the ICEA optical fiber cable documents which are ANSI-recognized U.S. National Standards. ANSI/ICEA S-87-640-2006, the standard for outside plant optical fiber cable and GR-20-CORE, Telcordia Technologies specification for outside plant fiber and fiber optic cable are pertinent to fiber and fiber ribbon, and ribbon cables referenced in this document. Sterlite Technologies ribbon cables described here comply with the requirements and test methods of these standards.