29 September 2021, Versowa, Mumbai – It was 11 A.M., a busy weekday for many. Ajay was in the midst of a critical presentation. He was the product manager of his company and was pitching a new product to the board members. Suddenly, the connection was lost and there was a blackout on his screen. He tried to connect through a hotspot but the signals were very weak. The internet had again gone blackout. The reason? Due to some ongoing construction work on roads, a major optical cable was cut. As the road is always busy with heavy traffic till 1 A.M., the service provider took around 2 days to repair. The service provider had to dig into the ground and access the problem and re-splice in more than one place. Internet services experienced a mega outage as thousands of students and workers were left without Internet amid ongoing online classes and work meetings.

The problem of internet outage was not new to the 15 km circle where the connection was being provided through the optical fibre network spread between Versowa to Ghatkopar. It was the third internet outage in 6 months in one of the most posh areas of Mumbai. All connections ranging from broadband to even mobile networks were sometimes down in regions

Challenge: Frequent internet outages owing to ongoing civil work

While fibre optic networks are essential to modern communications, they’re also vulnerable to damage. Outages happen regularly, despite service providers’ guarantee of reliability and uptime. The circumstances leading to most outages are beyond their control.

Every year, thousands of optic fibre cables that provide household connections are severed during road excavations. It could be digging a trench for installing new water mains, landscaping and paving work, or other utilities digging to repair their infrastructure. And telecom providers can do nothing except send someone to fix it. Construction work can interfere with broadband connectivity because of the heavy equipment involved. Sometimes the damage is really hard to access due to busy roads and heavy movements.

Network outage hurt customers and the community. Service providers spend ~INR 2 crores every downtime along with the pain of taking lots of permissions from civic authorities to perform digging and trenching in such a long stretch. Now it was the time to put an end to outages and welcome the #NeverDown technology.

The service provider started looking for a permanent solution to this recurring problem.

Finding an alternate path for laying the network

The solution provider reached STL’s team of engineers with this peculiar problem of finding an alternate route for laying fibres. Our team of engineers did a deep dive research and found a solution in laying the fibre along the metro line that spread a 12 km stretch between Versowa to Ghatkopar.

The idea of laying a fibre network along the Metro line really clicked with the solution provider. The benefits of laying an optical network along the metro were many:

- Increase in the longevity of network to up to 20 years as there was no scope of civil work in that route

- Reduction in the overall cost by ~60%

- Maintenance-free network as fibre was to be placed along the metro track

- Seamless connectivity with high bandwidth

Though the benefits were many, the next step was the execution of this network design.

An uphill task of network deployment began

Though the concept of building a network along the metro track was excellent, the team was unaware of the execution challenges that were to be faced.

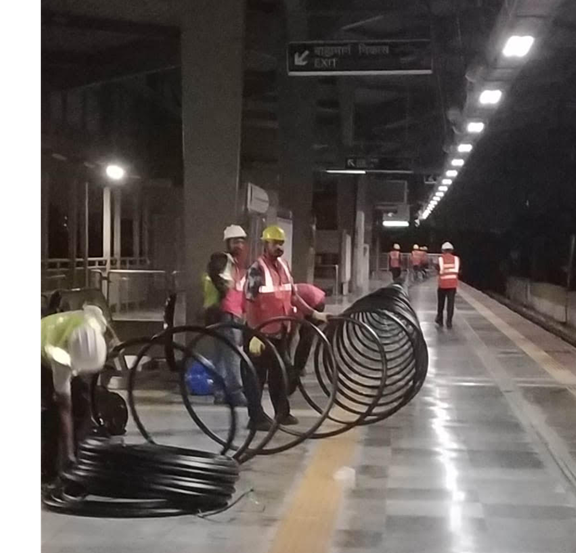

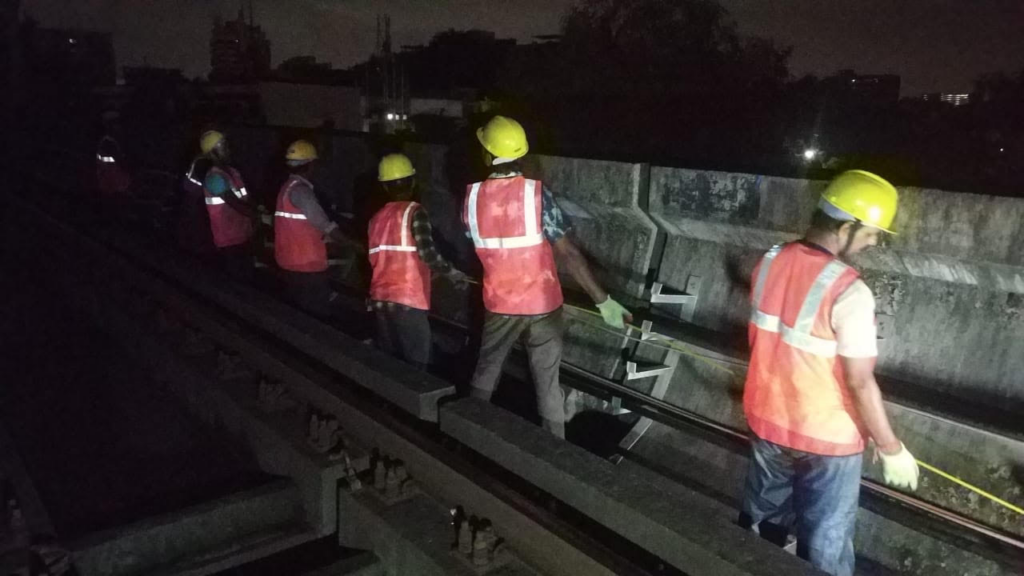

The biggest challenge in laying the fibre along the track was time constraints. The metro operations were only shut between 1 A.M. to 3 A.M., that is for 2 hours daily. So the team could only get to work in those 2 hours. Secondly, all the engineers entering the metro track to do deployment work had to be trained and certified according to the parameters laid by Metro Authorities. This also took a lot of time as our 40 engineers were trained and certified accordingly.

There was one more condition laid by the authorities that the team cannot leave any equipment including cable barrels after the work was finished. As the track was built 52 feet above the ground, clearing the track daily was really cumbersome for the team.

But the team did not give up. They built a 3-way duct of 12-14 mm for blowing three 96 Fibre count cables. For this, special blowing machines were used that can fasten up the deployment job and ~39 km optical fibre cable was laid. The team used specially designed universal ADSS (All-dielectric Self-supporting) optical fibre cable. The cable is jacketed to protect the fibres from moisture and the effects of UV light and a layer of aramid yarns (Kevlar) to improve their tensile strength.

Despite all these constraints, this uphill task of deploying an optical fibre network along the track was completed within 6 months.

The service provider conducted field testing after installing this cable. After a few trials, the field tests were successful. The network was tested for speed, bandwidth and longevity. The entire optical cable network was now replaced.

It has been 2 months since deployment. The civil work like road construction, etc, is still going on as it was happening before. But there has been no impact on quality and speed of the service provider’s new network.

Who knew that the Metro Railway Line, lifeline of a city like Mumbai, will become the backbone of high-speed broadband network!