Between 1950 and 2017, global plastics production increased 174-fold and it’s projected to double again by 2040. In 2020 alone ~380 mn tons of plastic was produced. About 79% of the plastic waste generated by this production ends up in landfills or the environment. Only 9% is ever recycled and only one-tenth of that amount has been recycled more than once over the last 50 years.

Because most plastic is made from fossil fuels, it contributes to climate change. At the moment, roughly 11 million tonnes of plastic flow into the ocean each year, and this number is expected to almost double by 2040. Plastic pollution has the potential to impact both land and sea ecosystems, and its presence has been documented across the entire planet, spanning from the Arctic region to the most remote depths of the ocean.

IT and telecom companies contribute to the plastic waste problem through various means, including packaging materials, electronic devices, and other plastic components.

Electronics and IT products often come packaged in plastic materials such as shrink wrap, plastic trays, or bubble wrap. While some companies have made efforts to reduce packaging waste and switch to more sustainable alternatives, plastic packaging remains prevalent.

The global community faces a pressing plastic crisis that necessitates immediate and collective action. The existing approach must be revised. Plastic pollution poses a significant and urgent global challenge that demands the participation of all relevant stakeholders across various levels to address effectively.

By investing in infrastructure and innovation, stakeholders in the plastics value chain can act as a catalyst for local efforts all around the world

Packaging is one of the biggest contributors to the carbon footprint

Plastic’s widespread utilization began with the discovery of “Polyethylene” in 1933, marking its emergence as a packaging material. Subsequently, in 1977, the plastic grocery bag was introduced, further solidifying plastic’s role in packaging. Recognizing the correlation between the plastic surge and the excessive utilization of packaging is crucial.

Plastic packaging has brought about a transformative impact on the storage, transportation, and consumption of products, offering convenience, durability, and adaptability. Nevertheless, the rapid surge in plastic consumption has given rise to a grave environmental predicament. Insufficient disposal methods and inadequate management of plastic waste have led to pollution, depletion of resources, and ecological damage. The packaging sector significantly contributes to the accumulation of plastic waste, necessitating immediate attention and concerted efforts to create awareness and combat this urgent concern.

Containers and packaging constitute a significant proportion of the solid waste produced i, totalling 82.2 million tons in 2018 (equivalent to 28.1% of the total waste generated).

Sustainable operations encompass a significant aspect of packaging – The transportation of fibres and cables to customers necessitates packaging. This involves the utilization of plastic spools, cardboard boxes, wooden drums, pallets, and steel drums.

We understand that sustainable packaging is the best answer to this

STL works with partners to develop green, reusable packaging material and source durable and disaster-proof raw materials that are capable of withstanding natural calamities.

At STL, we contribute to recycling efforts by repurposing wooden waste and drums to produce pallets. Additionally, we are actively exploring the implementation of reusable packaging alternatives to minimise reliance on new raw materials.

We are working with partners to develop better solutions for our packaging needs. We have developed green, reusable packaging material and source durable and disaster-proof raw materials that are capable of withstanding natural calamities

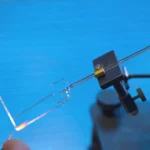

This has led to simple, but significant innovations — the latest being the Ultra-Light Weight Cable drums developed together with Networks Centre, UK. This is aligned with the UK government’s Sustainability Plan.

The challenge of heavy cable drums – Weighing 130 kilograms each, the ultra-lightweight (ULW) cable drums presented multiple challenges in terms of shipping, cost, and cable protection.

Handling, transportation, and re-reeling at the customer’s end were also arduous tasks. The large size of these drums prevented their storage on pallet racks, requiring upright storage that occupied significant warehouse space. Moreover, the bulky drums posed difficulties for customers during offloading and acceptance of the cable. The requirement was for smaller, lighter reels that could ideally be managed by a single individual.

We devised a solution to reduce plastic footprint – In collaboration with Networks Centre’s technical, warehouse, and cable reeling teams, an optimal solution was developed using compact reels. This innovation enabled STL to transport six drums within the space previously occupied by one. This was managed by a single person and resulted in a remarkable increase of over 60% in shipping capacity reducing loading time by 75%.

Furthermore, the new design contributed to significant environmental benefits by saving 2.28 metric tons of plastic and reducing carbon emissions by 50 tCO2e through the use of less polypropylene, optimising container use. The smaller drum size not only facilitated more cost-effective transportation but also minimized cable damage during shipping. The streamlined dimensions allowed for easy pallet fitting, ensuring minimal to no movement during transport, unlike the earlier bulkier drums that required stacking due to their size.

As a result, the loading time for shipping drums was reduced to one-fourth of the previous requirement, despite the increased quantity being loaded.

We have been doing our bit to reduce carbon footprint from environment and all businesses must inroporate sustainable practices in their operations.

By utilizing eco-friendly materials like biodegradable or recyclable alternatives, sustainable packaging reduces the reliance on non-renewable resources and helps mitigate the negative impact on the environment. Additionally, sustainable packaging often employs lightweight designs that minimize transportation-related emissions, as lighter packaging requires less energy for shipping and reduces fuel consumption. Moreover, sustainable packaging encourages responsible consumer behavior, promoting recycling and proper disposal practices. By adopting sustainable packaging solutions, businesses and individuals can significantly contribute to the reduction of greenhouse gas emissions, conserve natural resources, and create a healthier, more sustainable future for our planet.