Embodying Sustainability for Lasting Change

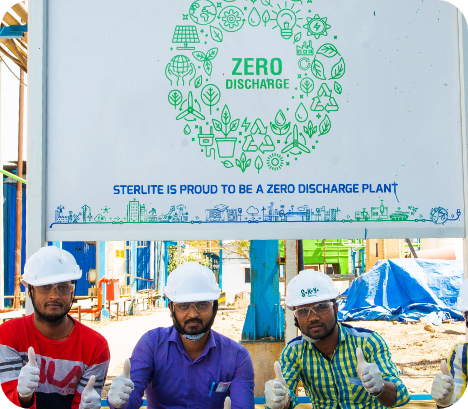

While we transform ourselves to function in a more social and environment-friendly way, we recognise that the world’s major issues can only be mitigated through a collective approach. STL has been collaborating with its suppliers, customers and other partners to develop newer and more innovative ways of working.

Through these, we aim to deliver life-changing technologies for communities, reduce our environmental footprint through system-wide approaches, ensure our people are engaged and inspired to drive inclusive growth, stay safe and healthy as well as create sustainable business models that will drive shared value.